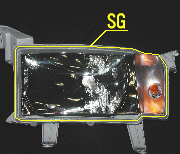

Sealing agents (SG)

The Asahi Tack SG Series is a hot melt sealing agent of next generation that is very soft (low compressive stress), returns to the original shape (low compressive strain) and has both high heat resistance and durability that are not available with conventional hot melt adhesives.

The Asahi Tack SG Series does not contain any solvent and can be used on automated lines. For this reason, it is friendly to the environment and economical.

It has such impact absorption properties that an egg will not be broken when it is dropped onto it. It has also the properties of returning to the original shape.

Our tackifers are used for a wide range of applications such as automotive and building materials, various bonding/sealing materials for electric appliance use, and amenity goods including mattresses and chair cushion materials.

Please feel free to contact us and look at samples.

| Product | Characteristics |

|---|---|

| Asahi Tack SG Series | Flexible hot melt type sealing agents (patented) |

<Automotive head lamp>

<An example of flexibility>

<Example of easy pealability

and good workability>

Because of its characteristics of flexibility, sealing performance, easy pealability, heat resistance and high workability, the Asahi Tack SG Series has been used for the following broad range of applications:

- Head lamps, tail lamps and other automotive trims

- Refrigerators, washing machines, dishwasher-drier machines and other electric appliances

- Roof and wall sealing agents and other building materials

- Floor cushions, floor mats, bed mattresses and other cushion materials

Characteristics of the Asahi Tack SG Series

| Flexibility | It has excellent flexibility that is not available with conventional hot melt adhesives and has such impact absorption properties that an egg will not be broken when it is dropped onto it. |

|---|---|

| Sealing properties | Because of its flexibility and shape recovery properties, it will show sealing effect when it is put soaked between different types of substrates. |

| Easy pealability | After used for the sealing of different types of substrates, it can be peeled off easily. This makes it possible to separate and recover the substrates. | Good workability | A combination of the SG Series and a robot will make automatic application possible. The use of the SG Series will have a cost reduction effect through a labor saving in the customer’s production process and an improvement in productivity. |

Classifications of Hot Melt Applications

- Bookbinding

- Packaging

- Electric appliances

- Automobiles

- Building materials

- Tackifiers

- Sealing agents (SG)