We will provide assistance to those customers who are using, or studying the use, of hot melt adhesives, starting with the identification of the issues to be resolved at the site, so that higher quality and efficiency will be achieved.

Industries to Which Our Equipment Has Been Delivered

- ● Automobiles

- ● Bookbinding

- ● Building materials

- ● Food and beverages

- ● Electric appliances

- ● Information, communications, etc.

Scope of Equipment Available from Us

- ● Coating test*

- ● Equipment/mechanism design

- ● Housing design

- ● Circuit design

- ● Programming equipment assembly

- ● Installation

- ● Test run

- ● Repair

- ● Overhaul

* Prior confirmation can be made by using a robot, a roll coater, and molding equipment, etc.

Equipment

Melting device

<Applicator>

We will propose optimum equipment according to the viscosity and temperature of the hot melt adhesive and the amount of usage.

- Applicator(Melt grid type)

- Bulk meter(Platen melt type for drums and pail cans)

- PUR, etc. applicators(Sealed, nitrogen-purged-type melting equipment)

- Molding melter(On-demand melting type)

Coating device

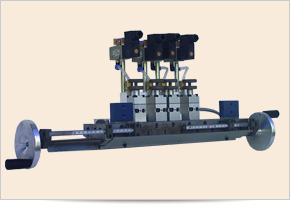

<Variable T die>

<Melter gun>

We will propose such coating equipment as bead, spray and curtain coating equipment to suit the substrate to be bonded.

- Variable T die(Curtain coater that allows the coating width to be changed freely.)

- Chamber-type automatic gun(Capable of charging a constant amount precisely)

- Roll coater(that coats the adhesive uniformly on the top of the substrate)

- Melter gun(A handy-type gun for use in small-volume production, repair, etc.)

Peripheral equipment

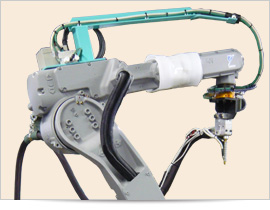

<Robot (6-axis)>

We carry out the design of the mechanism, robot (6-axis, 3-axis, etc.) and transfer equipment (conveyor, crane, etc.) for specific use by a customer by combining melting and costing equipment to achieve the automation of the production process.

Quality control equipment

<Page pull tester>

The equipment measures the adhesion of the substrate for quality control purposes.

- Page pull tester(Capable of making digital measurement of the adhesion of paper products)

- Oven time tester(that measures the oven time of the adhesive)

Production auxiliary equipment

<Melt cutter>

For a labor saving in production

- Melt cutter(that cuts large blocks of an adhesive or a tackifier into small pieces0